PRODUCT CATEGORIES

HOT PRODUCTS

ABOUT US

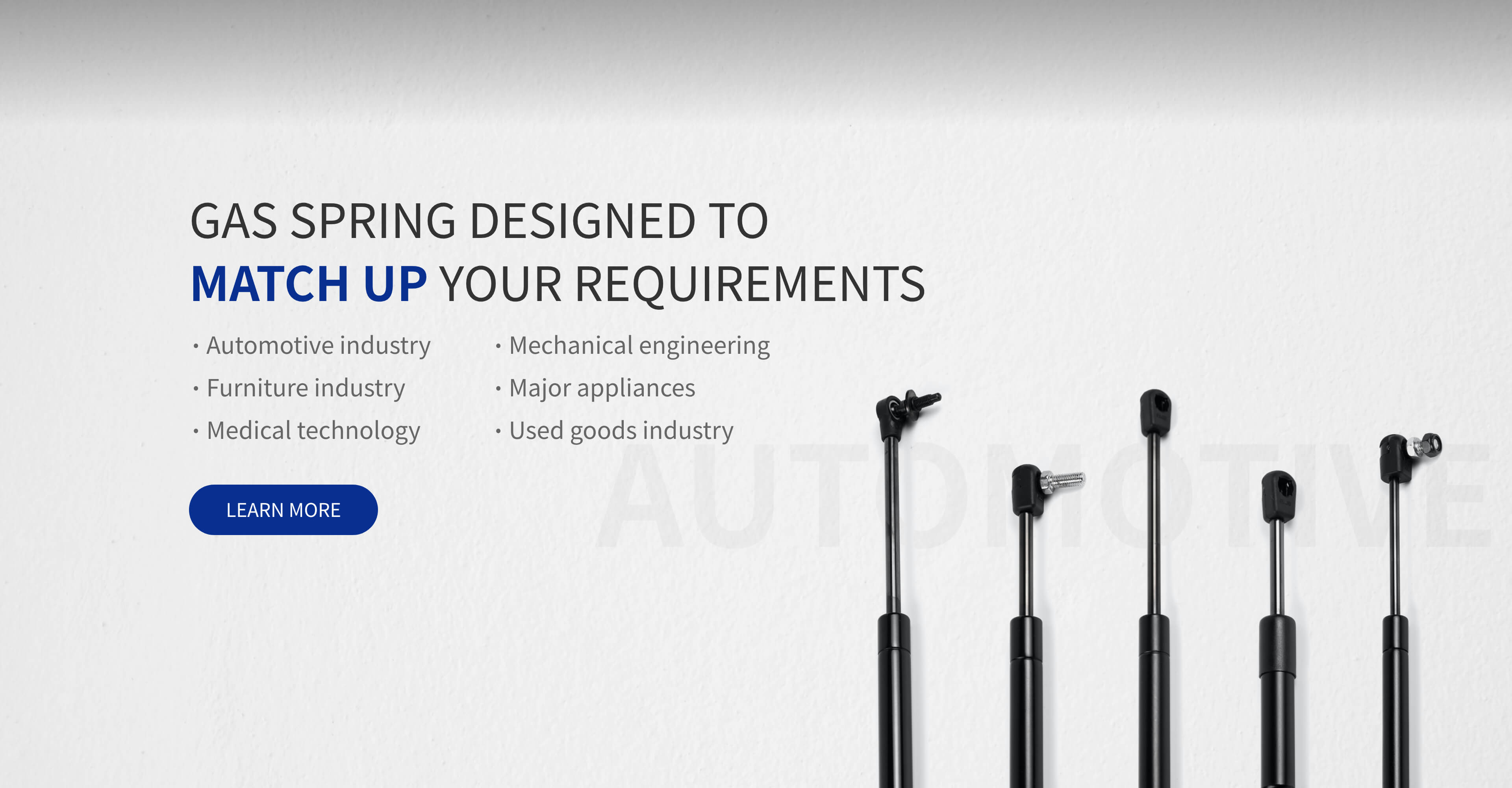

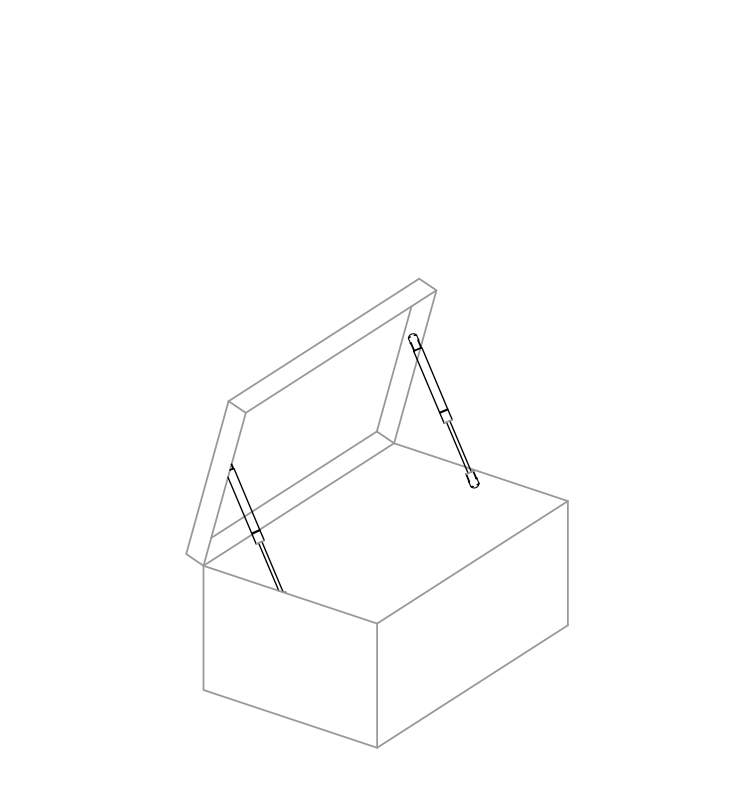

ChangZhou Juteng Gas Spring Co., Ltd. The Company was established in 2009, it is a specialized manufacturer which dedicated to gas spring research and development, production and sales.

Juteng with a high degree of professional guidance, successively developed various types of gas spring, a total of four series more than 300 varieties, application in car, furniture, machinery, medical treatment, the ships, the farm machinery, construction machinery ,dustbin and other industries, also can make special gas spring according to the special requirements by customers’ need, it has been formed with the annual production capacity of 1.5 million production.

Our company is dedicated to provide customers with excellent service, high quality, the best price and on time delivery in order to cater for customers' demands. We warmly welcome OEM / ODM orders as well as design and manufacture of new models with customer's label or logo are enthusiastically accepted.

We sincerely look forward to establishing long-term, reliable and mutually beneficial business partnerships with all customers from at home and abroad.

Juteng with a high degree of professional guidance, successively developed various types of gas spring, a total of four series more than 300 varieties, application in car, furniture, machinery, medical treatment, the ships, the farm machinery, construction machinery ,dustbin and other industries, also can make special gas spring according to the special requirements by customers’ need, it has been formed with the annual production capacity of 1.5 million production.

Our company is dedicated to provide customers with excellent service, high quality, the best price and on time delivery in order to cater for customers' demands. We warmly welcome OEM / ODM orders as well as design and manufacture of new models with customer's label or logo are enthusiastically accepted.

We sincerely look forward to establishing long-term, reliable and mutually beneficial business partnerships with all customers from at home and abroad.

COOPERATIVE PARTNER

FAQ

- 1-5

- 6-10

- 11-15

- 1.Why is there a warning on the gas spring?

- Gas springs are filled with compressed nitrogen. The warning is intended to prevent unauthorized people from opening the gas spring or making other changes to the gas spring, which negatively impact the strength of the pressure pipe.

- 2.Can gas springs explode?

- No. The pressure pipes of all JUTEN pressure pipes have wall thicknesses and materials that are dimensioned so that there is a sufficient level of safety against bursting in all conceivable functional states.

- 3.What are JUTENG gas springs filled with?

- Only nitrogen is used as the pressure medium in JJUTENG gas springs. About 75% of the air we breath consists of this gas. Nitrogen is absolutely safe and harmless to health. In addition, nitrogen does not burn. On the contrary, nitrogen is used in the chemical industry to prevent and extinguish fires. In addition, every JUTENG pneumatic spring contains flame-retardant oil to lubricate the seals and to achieve certain functions, such as damping or rigid locking.

- 4. How high is the pressure in a gas spring?

- The filling pressure of JUTENG gas springs depends on the extension force and the geometry and is between 5N and 3000N.

- 5.How does a gas spring work?

- Inside a gas spring, the filling pressure acts on both surfaces of the piston. Once this is firmly bonded with the piston rod, the piston surface on the piston rod side is reduced by the cross-section of the piston rod. This results in a differential pressure on the piston, which acts in the extension direction. The size of the force [F] is equal to the product from the filling pressure [p] and the piston rod cross-section surface [A]. The following formula applies: F = p x A

- 6. What is ‘’F1’’ force?

- The "F1 force" is the designed force of gas springs. This is measured when the piston rod of the gas spring is extended to 5 mm. It should be noted that the measured point of a significantly shorter position is approached with a defined speed and the value of the "F1 force" is read only about 3 seconds after the measurement devices comes to a standstill. The measurement must take place at 20°C gas spring and room temperature.

- 7.Does the force of the gas spring change when displacing the piston rod?

- Yes. The inner volume of the gas spring is closed to the outside. This means that the filled gas volume can only occupy the free space in the pressure pipe that is not needed for components or oil. By pushing the piston rod in, this free space [V] is reduced by the inserted piston rod volume. Because the same gas volume has a smaller volume available, the pressure [p] in the gas spring increases. This formula applies: p2 = (V1 / V2) x p1 The index [1] corresponds to the piston rod position before moving displacement and index [2] after displacement. The force [F] can also be used for the pressure [p] in this formula due to the correlation of the gas spring force with the filling pressure.

- 8.Is it possible to manufacture a gas spring without friction?

- No. So that the gas filling does not escape from the pressure pipe, a hermetic seal of the gas spring interior must be created, even at the moving piston rods. To achieve a hermetic seal, the piston rods and the seal must be in contact with a sufficient surface pressure. The result of the contact of two bodies is always a frictional force. The sealing of JUTENG gas springs is designed so that the piston rods slide on the seal when displaced. The resulting friction is reduced to a minimum in gas springs due to a careful selection of the materials and lubricants used.

- 9. Can the damping of gas spring be changed?

- The damping of gas springs can be preset by using different "damping discs." Furthermore, special "damping" (e.g. end position damping or insertion damping) can be achieved by filling with larger oil quantities. Here, a larger resistance must be overcome to press the oil through the piston than if gas is flowing through the piston.

- 10. How long is the service lift of a gas spring?

- The general service life of gas springs is between 10,000 and 50,000 double strokes (1x retraction and extension) depending on the type of gas spring. At JUTENG, the service life is tested according to internal test standards. These test standards provide for an optimal installation of gas springs. After the service life tests are completed, only a minimum power loss from escaped gas is tolerated at JUTENG. However, the actual service life of a pneumatic spring in application depends on many factors. That is why gas springs should be tested in the respective application under the actual conditions to be able to make a reliable statement about the service life of the gas spring.

- 11. Should gas spring be installed with the piston rod facing up or down?

- In general, gas springs should be installed with the piston rod facing down to ensure the piston rod seal is lubricated and to reduce the permeation of nitrogen through the seal. However, the opposite installation may be necessary in some special cases, for example if the gas spring requires a very specific damping characteristic. In such cases, the lubrication of the piston rod seal must be ensured by special measures (space mat).

- 12. Does a gas spring have to be maintained?

- No. gas springs are equipped with a lubricant quantity during production that lasts a life time.

- 13. Can gas springs be repaired?

- No. All gas springs and dampers are by a plastic deformation of the external pipes during production. This makes it impossible to open the gas spring to replace individual components without destroying it.

- 14. How long can the gas springs be stored?

- The storage of gas springs has no negative consequences on their function if it is ensured that the piston rods point down and no dirt accumulates on the piston rod. If gas springs are not actuated for a long time, they only have a slightly increased amount of friction during the first retraction. However, this effect is equalized after the first actuation and the gas spring then again exhibits the usual friction values.

- 15. Does the temperature affect the function of gas springs?

- Yes. However, three temperatures ranges must be distinguished between. Between -40°C and +80°C (operating range), the temperature only affects the pressure of the gas in the gas spring. The temperature has an additional effect on the damping behavior of the gas springs. The temperature increase makes the oil be less viscous, which reduces the oil's resistance to the flow of the piston. This results in less damping. Likewise, the damping increases with a lowering temperature.

1.Why is there a warning on the gas spring?

Gas springs are filled with compressed nitrogen. The warning is intended to prevent unauthorized people from opening the gas spring or making other changes to the gas spring, which negatively impact the strength of the pressure pipe.

2.Can gas springs explode?

No. The pressure pipes of all JUTEN pressure pipes have wall thicknesses and materials that are dimensioned so that there is a sufficient level of safety against bursting in all conceivable functional states.

3.What are JUTENG gas springs filled with?

Only nitrogen is used as the pressure medium in JJUTENG gas springs. About 75% of the air we breath consists of this gas. Nitrogen is absolutely safe and harmless to health. In addition, nitrogen does not burn. On the contrary, nitrogen is used in the chemical industry to prevent and extinguish fires. In addition, every JUTENG pneumatic spring contains flame-retardant oil to lubricate the seals and to achieve certain functions, such as damping or rigid locking.

4. How high is the pressure in a gas spring?

The filling pressure of JUTENG gas springs depends on the extension force and the geometry and is between 5N and 3000N.

5.How does a gas spring work?

Inside a gas spring, the filling pressure acts on both surfaces of the piston. Once this is firmly bonded with the piston rod, the piston surface on the piston rod side is reduced by the cross-section of the piston rod. This results in a differential pressure on the piston, which acts in the extension direction. The size of the force [F] is equal to the product from the filling pressure [p] and the piston rod cross-section surface [A]. The following formula applies: F = p x A

6. What is ‘’F1’’ force?

The "F1 force" is the designed force of gas springs. This is measured when the piston rod of the gas spring is extended to 5 mm. It should be noted that the measured point of a significantly shorter position is approached with a defined speed and the value of the "F1 force" is read only about 3 seconds after the measurement devices comes to a standstill. The measurement must take place at 20°C gas spring and room temperature.

7.Does the force of the gas spring change when displacing the piston rod?

Yes. The inner volume of the gas spring is closed to the outside. This means that the filled gas volume can only occupy the free space in the pressure pipe that is not needed for components or oil. By pushing the piston rod in, this free space [V] is reduced by the inserted piston rod volume. Because the same gas volume has a smaller volume available, the pressure [p] in the gas spring increases. This formula applies: p2 = (V1 / V2) x p1 The index [1] corresponds to the piston rod position before moving displacement and index [2] after displacement. The force [F] can also be used for the pressure [p] in this formula due to the correlation of the gas spring force with the filling pressure.

8.Is it possible to manufacture a gas spring without friction?

No. So that the gas filling does not escape from the pressure pipe, a hermetic seal of the gas spring interior must be created, even at the moving piston rods. To achieve a hermetic seal, the piston rods and the seal must be in contact with a sufficient surface pressure. The result of the contact of two bodies is always a frictional force. The sealing of JUTENG gas springs is designed so that the piston rods slide on the seal when displaced. The resulting friction is reduced to a minimum in gas springs due to a careful selection of the materials and lubricants used.

9. Can the damping of gas spring be changed?

The damping of gas springs can be preset by using different "damping discs." Furthermore, special "damping" (e.g. end position damping or insertion damping) can be achieved by filling with larger oil quantities. Here, a larger resistance must be overcome to press the oil through the piston than if gas is flowing through the piston.

10. How long is the service lift of a gas spring?

The general service life of gas springs is between 10,000 and 50,000 double strokes (1x retraction and extension) depending on the type of gas spring. At JUTENG, the service life is tested according to internal test standards. These test standards provide for an optimal installation of gas springs. After the service life tests are completed, only a minimum power loss from escaped gas is tolerated at JUTENG. However, the actual service life of a pneumatic spring in application depends on many factors. That is why gas springs should be tested in the respective application under the actual conditions to be able to make a reliable statement about the service life of the gas spring.

11. Should gas spring be installed with the piston rod facing up or down?

In general, gas springs should be installed with the piston rod facing down to ensure the piston rod seal is lubricated and to reduce the permeation of nitrogen through the seal. However, the opposite installation may be necessary in some special cases, for example if the gas spring requires a very specific damping characteristic. In such cases, the lubrication of the piston rod seal must be ensured by special measures (space mat).

12. Does a gas spring have to be maintained?

No. gas springs are equipped with a lubricant quantity during production that lasts a life time.

13. Can gas springs be repaired?

No. All gas springs and dampers are by a plastic deformation of the external pipes during production. This makes it impossible to open the gas spring to replace individual components without destroying it.

14. How long can the gas springs be stored?

The storage of gas springs has no negative consequences on their function if it is ensured that the piston rods point down and no dirt accumulates on the piston rod. If gas springs are not actuated for a long time, they only have a slightly increased amount of friction during the first retraction. However, this effect is equalized after the first actuation and the gas spring then again exhibits the usual friction values.

15. Does the temperature affect the function of gas springs?

Yes. However, three temperatures ranges must be distinguished between. Between -40°C and +80°C (operating range), the temperature only affects the pressure of the gas in the gas spring. The temperature has an additional effect on the damping behavior of the gas springs. The temperature increase makes the oil be less viscous, which reduces the oil's resistance to the flow of the piston. This results in less damping. Likewise, the damping increases with a lowering temperature.